Cause:

1. Engine wear leads to poor compression. This in turn makes it difficult for the combustion process in glow engines to keep the glow plug ignited at low idle RPM values. Conditions are worse at idle where the cylinder head temperature is lowest.

This leads to deadstick events, particularly on landing where they often lead to aircraft damage.

2. If new engines are insufficiently run in or over ambitious idle speeds set then deadsticks of this kind can occur.

3. Long periods at idle in the air will stop most glow engines new or old, as the cooler conditions that occur in engines as time accumulates become unsupportable. This is not so with Permaglow.

Again the main point is this, if you are on finals and your engine cuts you can be looking at a damaged or written off aircraft.

Fix:

Fit On Board Glow, or Permaglow.

Comment:

The use of On Board Glow to solve this problem is well known and not covered here, save to say that the method uses switching circuitry which changes the mark space ratio of the glow plug energising current giving the maximum current at idle when it is needed most. This leads to decent battery life in such systems and is an advantage.

Permaglow is a less well known solution but can be very effective as a method of avoiding this problem.

Permaglow Principal:

C Size 3800 mAhr NiMH cells are used to power the glow plug throughout the model's flight.

The capacity of such cells are adequate to keep the glow plug ignited at all times and additionally serves as a means to start the engine. A model pilot simply takes a set of batteries pre charged for the days flying.

The main advantage to the system is circuit simplicity and reliability. The system is further improved by the use of cold plugs. Cold plugs by their design criteria contain robust filaments which are also known for poor idling performance, but this problem is overcome when Permaglow is used.

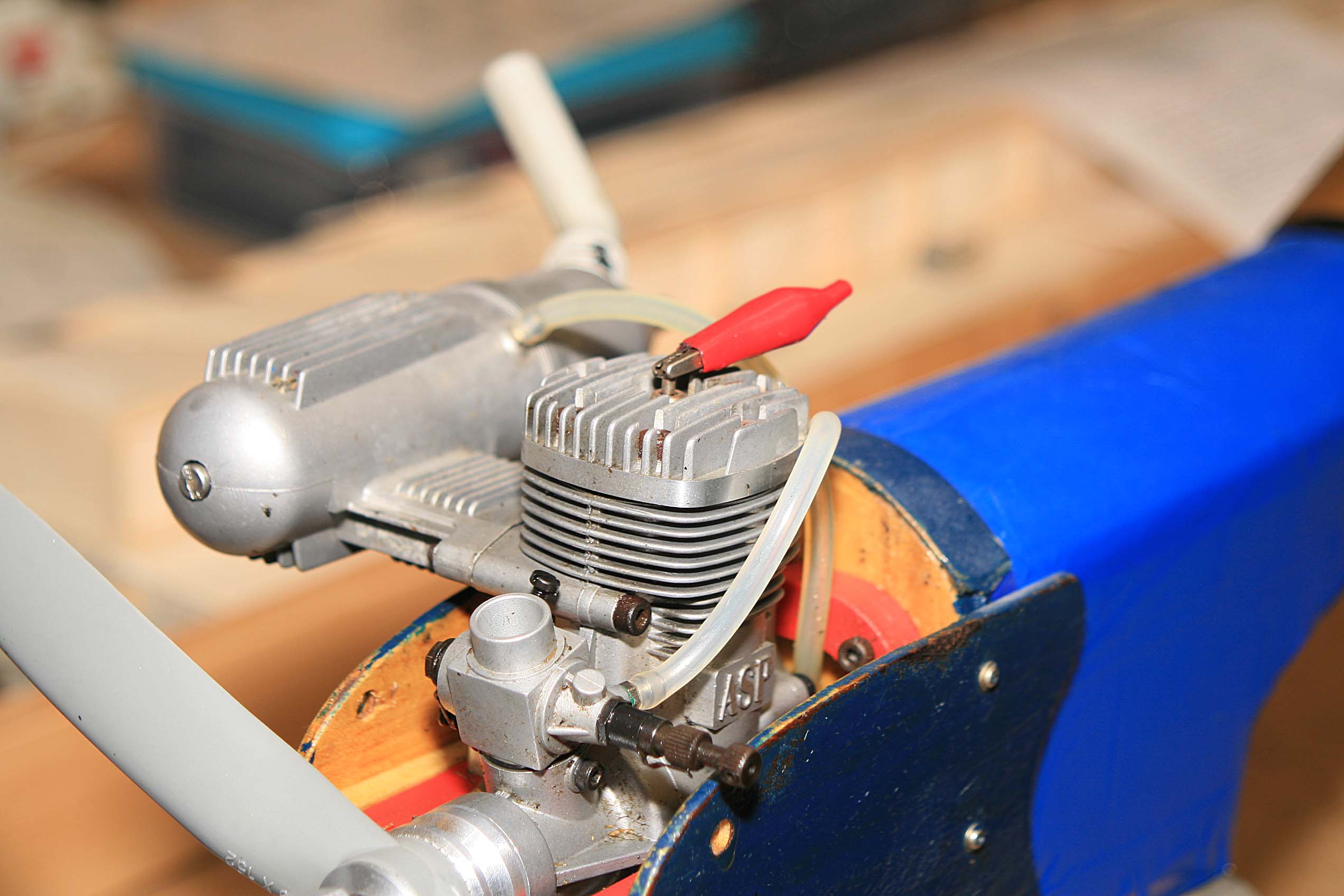

The attached photgraphs show typical installations and it's important to add that for durability no solder must be used in the circuit, i.e. crimped or bolted connections only, to avoid vibration failure.

People using this system rarely change glow plugs which often last for years.

Shows the 3800mAhr. NiMH positive battery connection connected directly to the glow plugs terminal

Shows a typical battery installation using crimped/bolted connections throughout.

Comments

Date: 16th. September 2017.

Title changed to better reflect the RCAeroBase format.

Causes changed from one to three.

Article released.